Forklift Truck Safety Signs-- Protect Your Group with Reliable Safety Markings

Forklift Truck Safety Signs-- Protect Your Group with Reliable Safety Markings

Blog Article

Forklift Safety Indicators: Necessary Tips for Ideal Placement and Presence

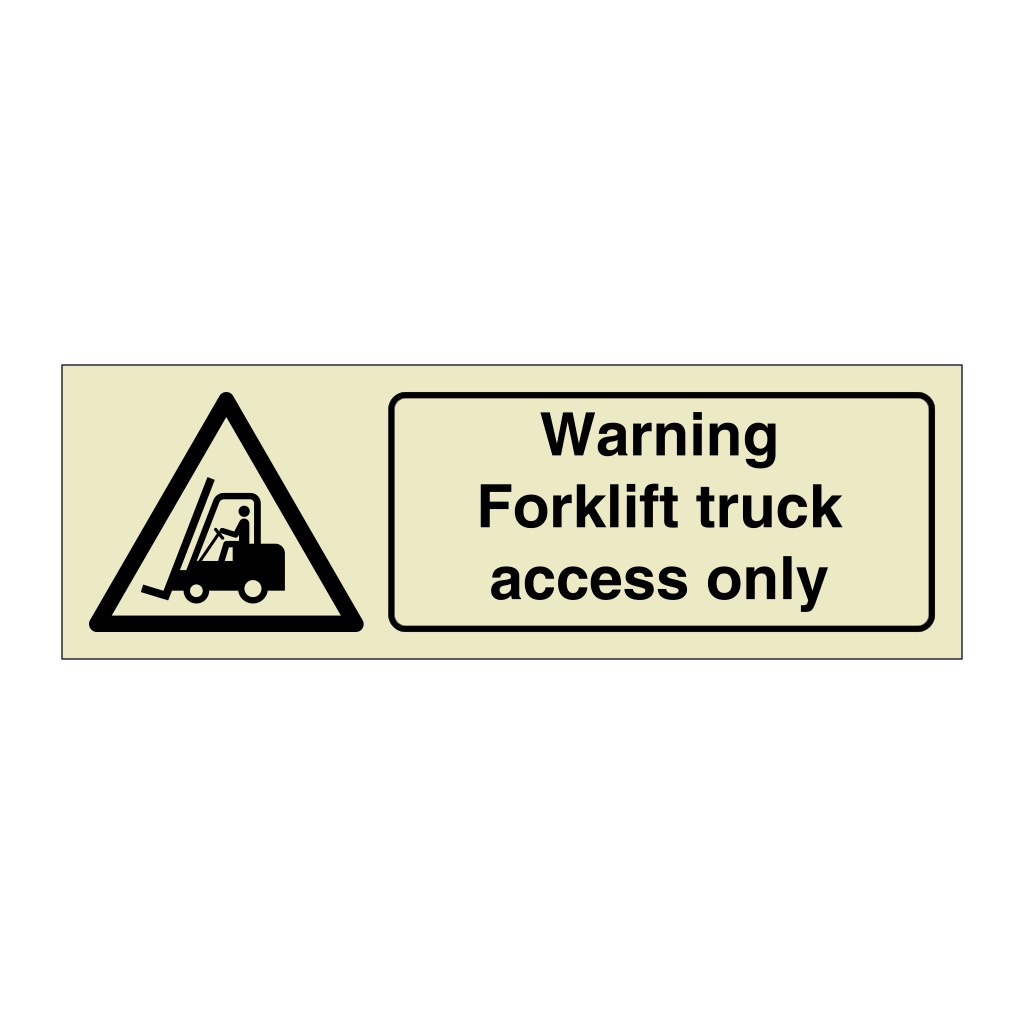

Guaranteeing the optimal placement and visibility of forklift safety indications is crucial in maintaining a secure industrial setting. Placing these signs at calculated locations such as access and exit points of filling anchors, vital facility intersections, and high-traffic storage areas can significantly mitigate accident risks. Mounting signs at eye degree and angling them towards oncoming traffic improves their performance. Additionally, utilizing sturdy materials and high-contrast designs guarantees long life and quality. Understanding the nuances of regular inspections and upkeep is similarly essential to copyright their performance-- what necessary steps should be taken to maintain these essential security tools?

Key Locations for Safety And Security Indications

Appropriate positioning of forklift security indications is critical for preserving a risk-free functioning atmosphere. Furthermore, putting indications near high-traffic storage space areas and blind spots can even more enhance visibility and awareness.

Junctions within the facility are an additional important area where accidents can take place; for that reason, quit indications and right of way signs are important. In pedestrian-heavy locations, indicators should signal both drivers and pedestrians to the visibility of forklifts, making sure every person continues to be vigilant.

Areas with high storage shelfs and blind places position special obstacles. forklift safety signs. Signs in these zones should advise drivers of minimal presence and urge the usage of watchmans or added safety and security actions. By focusing on these vital locations, companies can create a much safer, more reliable functioning setting for all

Height and Angle Factors To Consider

When installing forklift security signs, considering the elevation and angle of positioning is important to make certain maximum exposure and performance. Correct elevation ensures that operators and pedestrians can quickly see the indicators without obstruction.

The angle of the indicator is similarly crucial. Indications must be angled towards the line of sight of approaching traffic or personnel. If a sign is implied to alert forklift operators, it ought to be placed straight in their area of view, preferably vertical to their direction of traveling. In locations with several seeing angles, think about using double-sided indicators or tilted brackets to maintain exposure from different instructions.

Additionally, making certain that the signs are not blocked by various other things, equipment, or shelving units is crucial. Clear sightlines aid protect against mishaps and enhance total safety. By attentively considering elevation and angle, you can significantly enhance the efficiency of forklift safety indicators, therefore fostering a much safer job atmosphere.

Signs Product and Sturdiness

Choosing the ideal product for forklift safety and security indicators is essential for ensuring their durability and performance. In environments where forklifts run, indicators are typically revealed to harsh conditions, consisting of physical impacts, chemical spills, and varying temperature levels. Therefore, choosing durable products like light weight aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can substantially improve the indications' lifespan.

Furthermore, its lightweight nature facilitates very easy installment browse around here and repositioning. PVC, on the other hand, supplies a great balance in between sturdiness and cost-effectiveness, making it a common selection for lots of industrial atmospheres.

Furthermore, the printing approach used on these products also contributes in longevity. UV-resistant inks review and protective laminates aid in avoiding fading and damages from sunlight and various other environmental variables. Complying with these considerations makes sure that forklift safety and security indications continue to be visible and readable over extended durations, thereby preserving a secure working atmosphere.

Making Sure Sign Exposure

While choosing long lasting products for forklift safety indications is necessary, ensuring their exposure is similarly important for keeping a risk-free setting. Efficient exposure can be accomplished through calculated positioning, appropriate lighting, and utilizing high-contrast shades. Indicators ought to be positioned at eye level and in places where drivers and pedestrians are more than likely to see them, such as at entry points, intersections, and areas with high web traffic.

Appropriate lights is important to make sure that signs show up in all problems. Setting up ample lights in poorly lit locations or using reflective materials on indications can dramatically improve exposure. In addition, high-contrast shades and vibrant fonts should be employed to make the indicators quickly distinct from their environments. Making use of intense yellow histories with black text can guarantee that the message stands out.

Furthermore, avoiding visual clutter around the signs is vital. A lot of check in one area can overwhelm and puzzle individuals, minimizing the visit this page performance of each sign. Clear, succinct messaging and guaranteeing indications are without blockages such as devices or storage products will better improve their exposure and effectiveness, adding to a more secure office setting.

Regular Assessment and Maintenance

Consistency is crucial to maintaining the performance of forklift security indications, making routine assessment and maintenance essential. To ensure these indicators remain to connect crucial information clearly, they should be consistently inspected for deterioration, fading, or blockage. forklift safety signs. Gradually, exposure to the components and operational tasks can deteriorate their presence and readability, weakening their objective

An organized assessment timetable need to be established, with checks conducted at normal intervals. Throughout inspections, analyze each sign's condition, guaranteeing text and icons stay clear and lively. Any kind of signs revealing indications of damage or fading should be quickly replaced. Furthermore, make sure that indications are not covered by tools, stock, or other obstacles.

Verdict

Proper positioning and visibility of forklift security signs are crucial in lessening workplace mishaps. Positioning indicators at essential locations such as access and departure factors, center intersections, and high-traffic storage space areas, while guaranteeing they are placed at eye degree and tilted in the direction of oncoming traffic, boosts their efficiency. Using sturdy products like light weight aluminum and HDPE, along with high-contrast colors and strong fonts, even more boosts presence. Normal examinations and upkeep are necessary to maintain sign efficiency and promote a much safer working atmosphere.

Report this page